ABB NECA 2024 Case Study

ABB and Rogers Electrify at the NECA 2024 Trade Show

In 2024, and for the second consecutive year, ABB won the Best Booth Award at the NECA trade show. From the ingenuity and meticulous planning by ABB’s events and marketing team to the creativity and logistics solutions of the Rogers team, ABB was able to showcase how it is “powering the electrification of America”.

ABB set out to demonstrate its leadership in electrification and its ability to deliver comprehensive solutions across commercial, infrastructure and residential markets. The company’s vision was to present a unified, immersive experience for five of its product lines, promote its newest product solutions and engage attendees with memorable and interactive technology – all while maintaining cost efficiency.

A Winning Booth Strategy

The Rogers Company partnered with ABB to create an exhibit with maximum functionality, engagement opportunities and impact. This 80’ x 40’ island booth required creative design and layout, advanced technology and thoughtful logistics to meet ABB’s rigorous goals.

The focal point of the booth was a 50-foot backwall structure featuring a large LED wall that displayed key messaging and videos throughout the event. The booth theme of “Speed. Simplicity. Source to Socket. Powering the electrification of America.” was printed in large text directly on the structure, which also housed two conference rooms, secure storage and a hospitality area for visitors. The backside of the structure provided ample space for ABB to repeat the booth theme while also promoting its recent partnership with NASCAR.

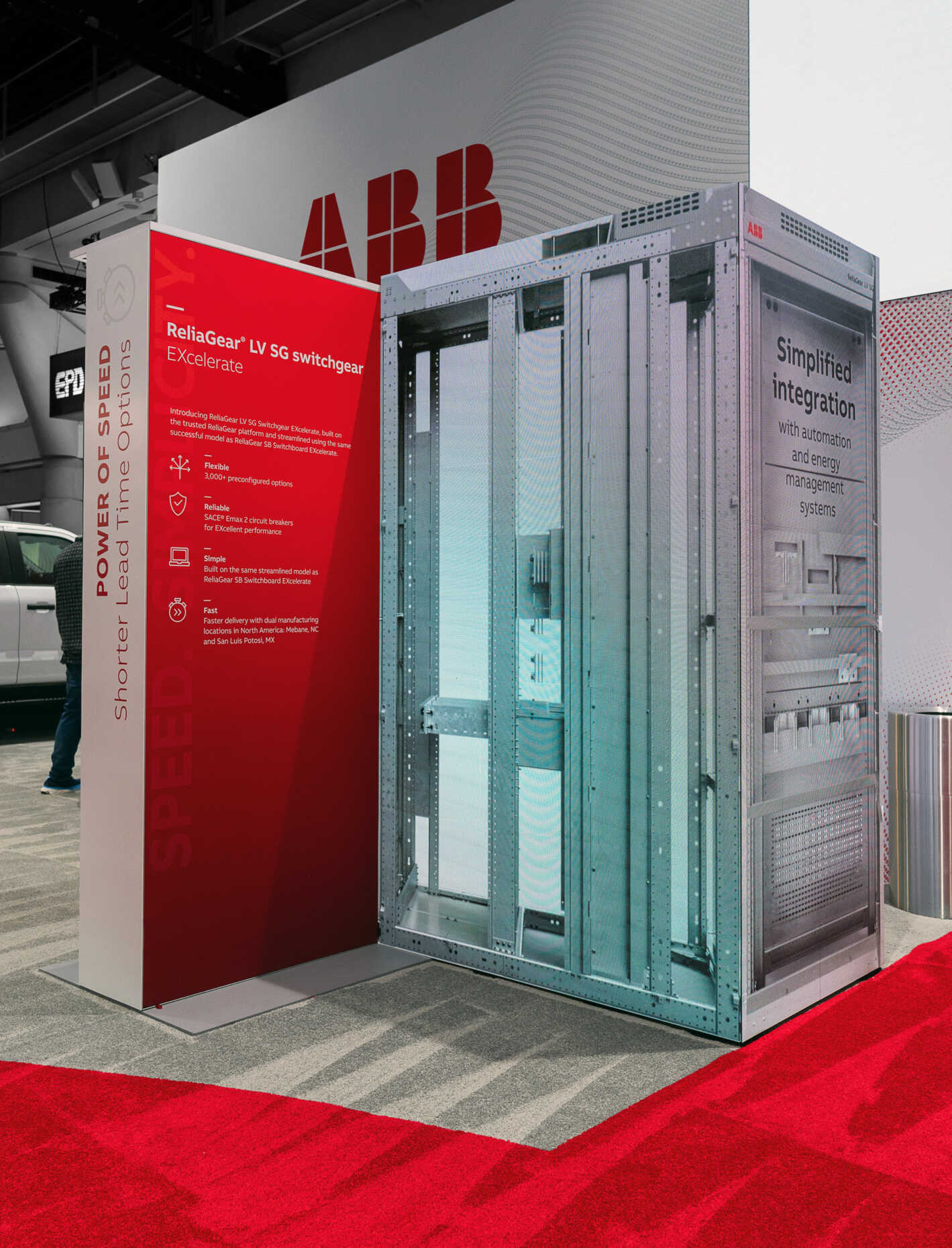

An exciting new booth feature was a virtual ReliaGear® EXcelerate switchboard. Rogers’ partner, Sentient Studios, assisted ABB with the development of a 3D modeled and animated configure-to-order (CTO) switchgear unit. This 3-sided digital display showcased how EXcelerate switchgear is delivered to customers in half the typical lead time, starting with the virtual manufacturing of a preconfigured base unit through custom add-ons to crating for shipping. Rogers then built and installed the unit, showcasing its capabilities in implementing advanced digital technology in its trade show booth design and build. As a result, ABB was able to easily explain its unique offering in an immersive way, while saving thousands on manufacturing, shipping and drayage costs.

Six, double-sided 8’ x 10’ product demo stations enabled ABB to promote its solutions in Smart Power, Smart Buildings, Distribution and Installation. Each station featured actual products for a hands-on experience and A/V monitors to relay key messaging. All four sides of each kiosk were printed with product information and its relevant theme message. Downlighting from the structures’ canopies brightened each space, making it easier for visitors to see and experience all the product details.

Two of these demo stations showcased ABB’s EPiC app, a tool that monitors and analyzes the performance of its equipment and allows remote control of breakers. Altogether, these demos lasted 7-10 minutes, so to get and keep visitors engaged, ABB utilized a stamp card that, once both demos were completed, would win that visitor a 40-ounce Stanley cup.

Four pedestal displays were utilized to promote essential commercial installation products. Each pedestal featured product samples, visually captivating graphics, key messaging and QR codes to learn more.

Taking center stage was ABB’s NASCAR EV stockcar, flanked by two interactive touchscreens showcasing ABB’s EV components and charging solutions. NASCAR Cup Series driver David Ragan joined ABB to conduct live demonstrations, interact with booth visitors and provide insight on ABB’s electrification initiatives within NASCAR.

The ABB mobile solutions truck, a hands-on demonstration and training center, features slide-out product boards, a cable protection application demo and an onboard a/v display. Attendees can schedule the truck to come to their facility for training via a prominent QR code.

A fun and engaging custom screen-printing station drew onlookers in from the aisles. Visitors were able to select from six whimsical messages printed on an ABB-branded t-shirt. Each message also played into the booth’s overarching ‘speed, simplicity and source-to-socket’ theme.

Customer engagement opportunities also included ABB’s in-booth hospitality, technical workshops and a “Top Gun” themed rooftop contractor event. Attendees and visitors also enjoyed ABB’s massive LED wall to watch college and pro football games during this weekend-spanning event.

Superior Booth Results

In addition to winning the 2024 Best Booth Award, several of ABB’s products also received NECA Show Stopper Awards. A nice feather in the cap of ABB’s product teams and all those involved in the planning and execution of this significant trade show booth.

According to Al Colquitt, US Events Director for ABB Electrification, business unit lead counts were more than double that of NECA 2023. In addition, 300 electrical contractors completed the EPiC demo and more than 400 visitors had custom t-shirts made in the booth.

The success of NECA 2024 also set in motion changes to ABB Electrification’s booth strategies moving forward. "The virtual switchgear display has really changed how we are going to show," said Al. “A lot of these units require forklifts and rigging, plus the internal order and freight charges. It’s a very costly endeavor,” he added. For future shows, Al envisions replacing actual switchgear units with virtual ones – a strategy that not only saves money but really engages his audience in the booth.

The Rogers Difference

“The greatest thing about working with Rogers is that they are a true partner,” Al attests. “Success is just as important to them as it is to me.”

Starting with an ABB-generated layout, Rogers helped ABB meet its goals for booth functionality and budgetary requirements. That original layout was significantly over-budget, so Rogers stepped in with recommendations and modifications to reduce costs while still delivering a high-impact, winning booth.

Rogers’ deep knowledge of ABB’s custom booth components ensured that the main structure could be efficiently fabricated on site, modifying the placement of the LED video wall and conference rooms. All of the A/V features in the booth were programmed and sourced through Rogers and its technology partners. Creative material selection and changes to walls and graphics helped to reduce costs.

"It’s the team that makes the difference, and the Rogers team is second to none."

“ABB, and specifically Al Colquitt, is a great customer who trusts us to bring their vision to life,” said Dina Jerinic, Account Executive at Rogers. “Our partnership is a true testament to effective collaboration and we look forward to achieving more milestones together.”

Rogers warehouses all of the electrification division’s booth properties in its climate-controlled storage facility, so each feature is protected from environmental damage. Before every show, the team at Rogers pulls and checks every display, replacing any wear items and ensuring each element is clean and show-ready.

And when it’s time for shipping, Rogers leverages its freight carrier partners to ensure the booth arrives safely and on schedule. Once at the show, the Rogers team supervises on-site labor to install and dismantle the booth, troubleshoot issues, and coordinate with union labor for utilities, flooring, rigging and material handling.

Al Colquitt concludes, “It’s the team that makes the difference, and the Rogers team is second to none.”

ReliaGear® is a registered trademark of ABB

From strategic planning and project management to exhibit design and technology to fabrication and warehousing to logistics, Rogers provides a full-service experience that keeps clients coming back for decades.

Make our team yours. Contact us today.

"*" indicates required fields